APX Insights

Zero-Point Clamping Fixtures: Why They Are Widely Used in Mechanical Manufacturing and Processing Industries

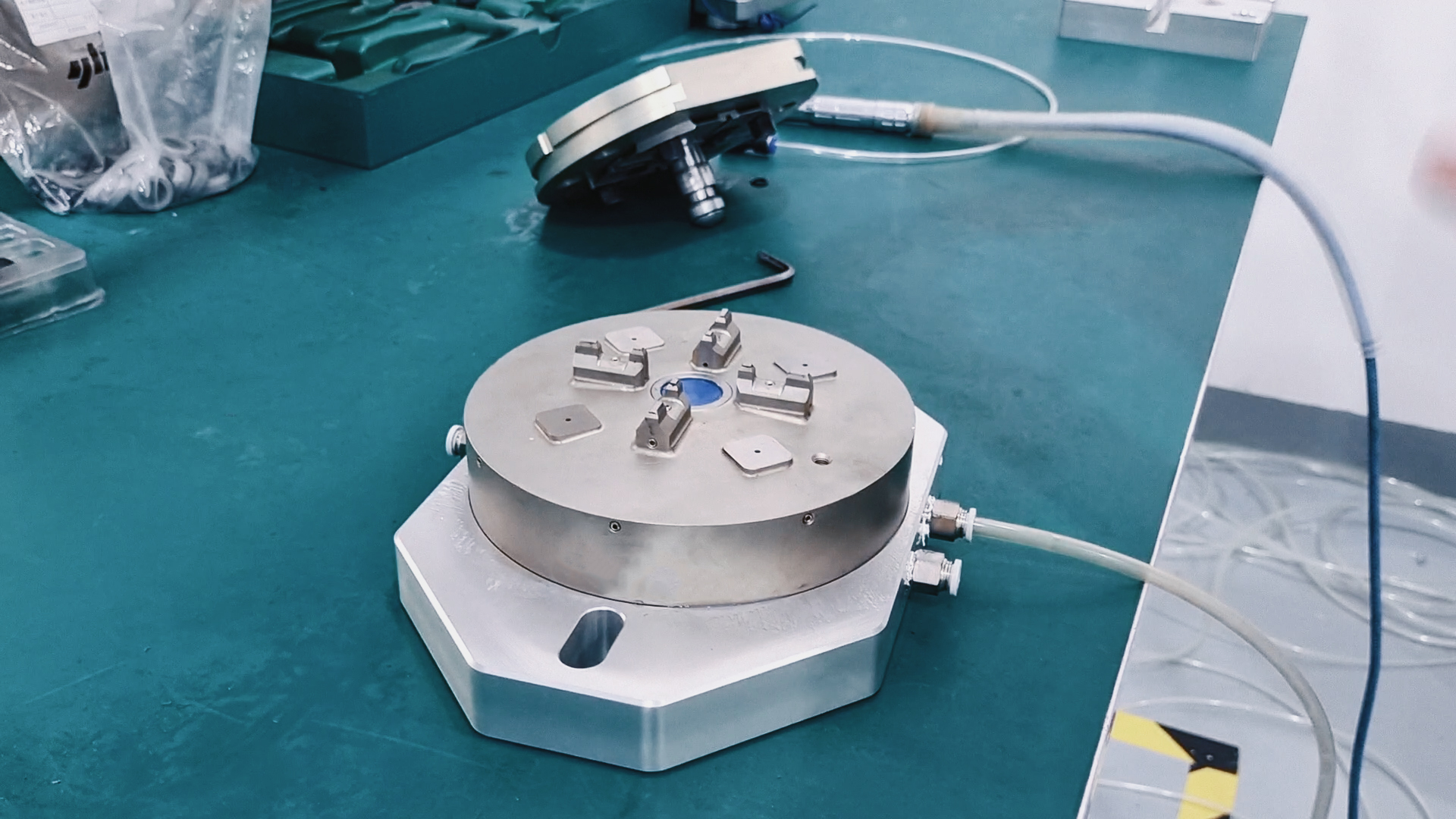

Zero-point clamping fixtures are unique positioning and locking devices that maintain the zero reference point of workpieces consistently across different workstations, processes, or machine tools. This consistency not only saves the auxiliary time spent on re-aligning the zero point but also ensures workflow continuity and improves work efficiency. By integrating high-precision positioning with reliable clamping, zero-point clamping fixtures establish a standardized interface between processes and machines. This allows workpieces to undergo multi-process machining after a single setup on the production line, eliminating the need to reconsider positioning and saving substantial auxiliary time.

Whether used with pallets, fixtures, vises, or workpieces themselves, zero-point positioning systems enable flexible and rapid changeovers when the zero point is established. If more machine tool tables are equipped with clamping plates, workholding fixtures across all equipment can be used more flexibly. For these reasons, such fixtures are widely applied in the mechanical manufacturing and processing industries.

Advantages of Zero-Point Clamping Fixtures:

1. Enhanced Work Efficiency: By maintaining the workpiece's zero position, it saves time on re-aligning the zero point, thus boosting efficiency.

2. Improved Machining Accuracy: The high-precision positioning and reliable clamping design ensure machining accuracy.

3. Rapid Changeovers: Zero-point clamping fixtures enable quick changeovers in just seconds, enhancing production efficiency.

4. Flexibility: They can collaborate with various equipment and workholding fixtures, allowing for more versatile applications.

5. Reduced Production Costs: By minimizing positioning issues and changeover time, production costs are lowered.

6. Higher Production Line Efficiency: Workpieces can undergo multi-process machining after a single setup, optimizing production line efficiency.

7. Simple Operation: Air supply releases the clamp, and air cutoff locks it, simplifying tedious clamping operations and reducing labor intensity.

In summary, zero-point clamping fixtures are efficient, high-precision, and quick-change fixture systems widely used in mechanical manufacturing and processing industries. They not only improve production efficiency, reduce costs, enhance machining accuracy, and enable rapid changeovers and flexibility but also boost a company's competitiveness.

Recommended news

-

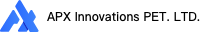

Machine Tool Probe Technology: A Key to Enhancing Competitiveness in Modern Machining

2025-05-26 -

Zero-Point Positioning System: The "Invisible Engine" of Machining Automation

2025-05-05 -

Zero-Point Clamping Fixtures: Why They Are Widely Used in Mechanical Manufacturing and Processing Industries

2025-05-05 -

Dual Guarantee for Machining Efficiency and Safety! In - machine Tool Presetter Makes Production Smarter

2025-05-05 -

Zero-Point Positioning Systems in FMS: Specific Application Scenarios

2025-04-25