APX Insights

Why the Machining Industry Belongs to Discrete Production Mode

The machining industry is categorized as a discrete production mode for the following key reasons:

1. Order-Driven Production with Customization

Products in the machining industry are typically manufactured according to customer orders, each with unique requirements and specifications. For example, part manufacturers may produce components of different models, sizes, and materials based on customer needs. This order-driven approach means each production run is tailored to specific demands rather than mass-producing identical items, granting the industry high flexibility and customization capabilities.

2. Dispersed Production Processes and Multi-Stage Operations

The production process in machining is often decentralized, involving multiple processes and departments. Part manufacturing may require operations like milling, turning, drilling, and grinding, each completed by different machines and equipment. It also involves collaboration with other departments, such as quality inspection teams for product testing. As a result, the production flow is not continuous but composed of discrete processes and stages.

3. Lengthy Production Cycles and Planning Complexity

Due to the uniqueness of each order and the multi-stage nature of production, machining products typically have long production cycles. This necessitates meticulous production planning to ensure orders are fulfilled by their deadlines. Additionally, enterprises must maintain inventory management capabilities to adapt to order changes or urgent requests, given the extended cycle times.

4. High-Precision Requirements and Rigorous Quality Control

Machining products demand high precision and quality, requiring each item to meet strict customer specifications. Thus, companies must implement rigorous quality control and inspection throughout production to ensure consistency, adding complexity and challenges to the discrete production model.

Conclusion

The machining industry’s classification as a discrete production mode stems from its order-driven manufacturing, dispersed multi-process workflows, lengthy cycles, and high-precision quality demands. While this model offers flexibility and customization, it challenges enterprises to master production planning, inventory management, and quality control to thrive in the sector.

Recommended news

-

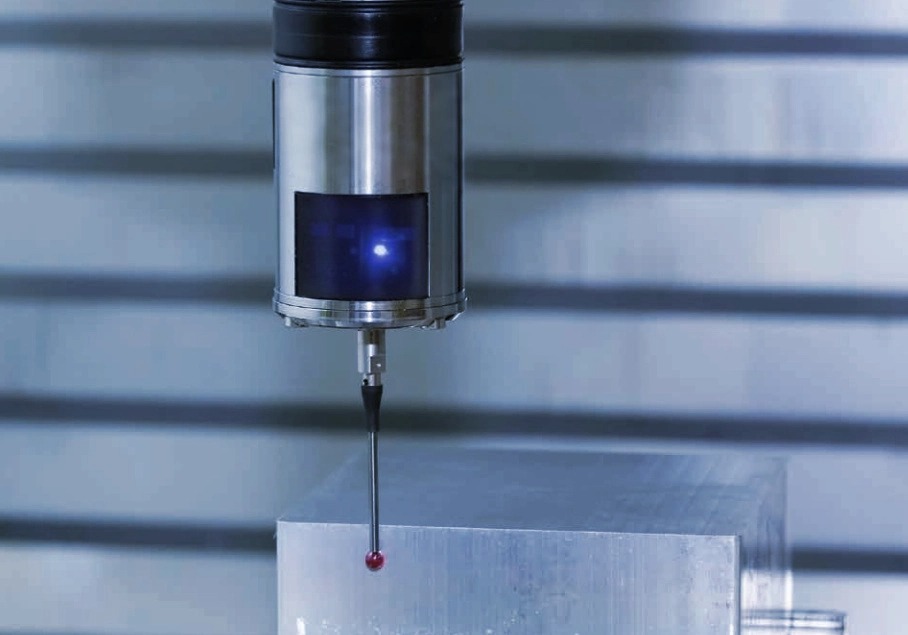

Machine Tool Probe Technology: A Key to Enhancing Competitiveness in Modern Machining

2025-05-26 -

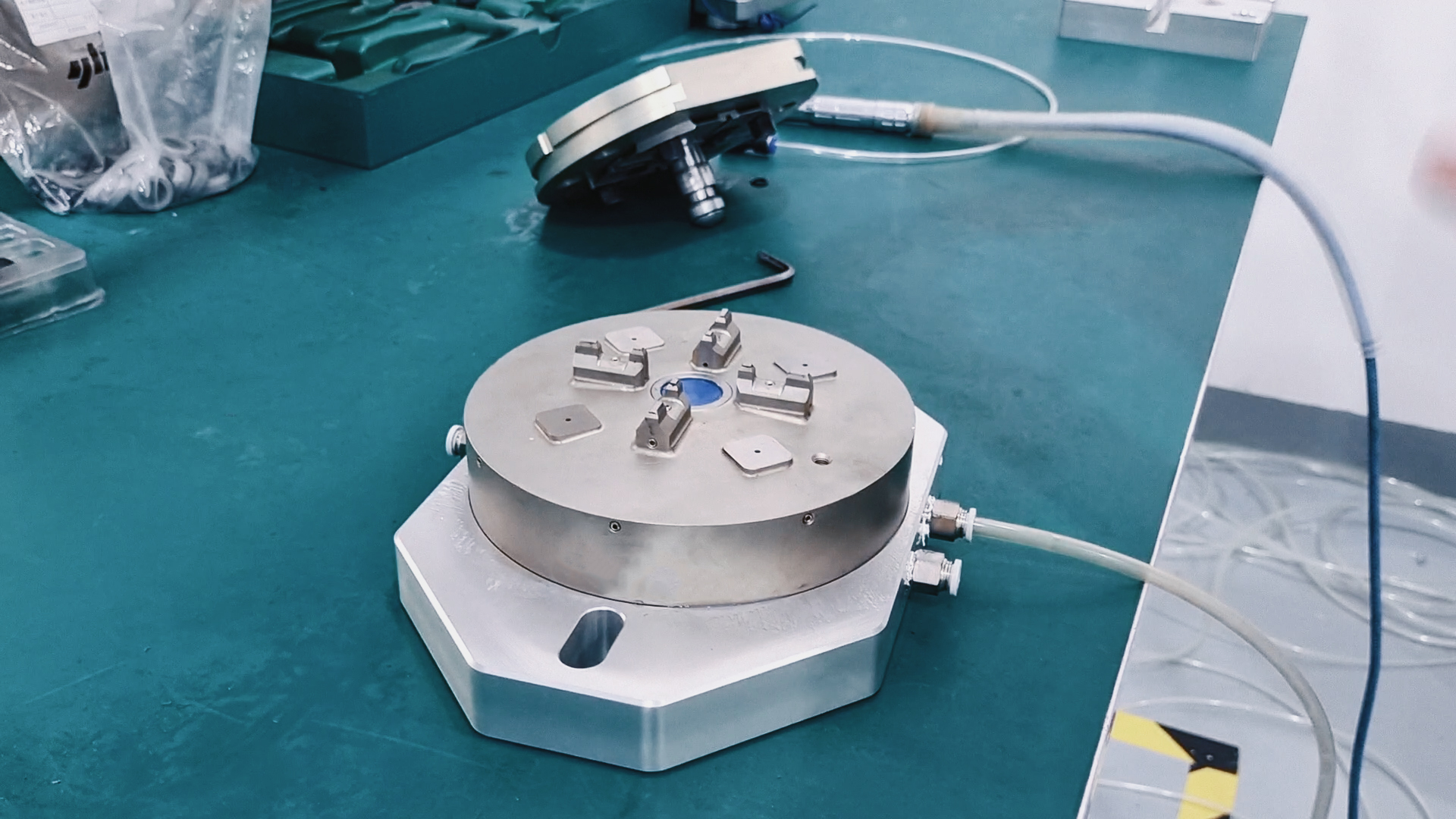

Zero-Point Positioning System: The "Invisible Engine" of Machining Automation

2025-05-05 -

Zero-Point Clamping Fixtures: Why They Are Widely Used in Mechanical Manufacturing and Processing Industries

2025-05-05 -

Dual Guarantee for Machining Efficiency and Safety! In - machine Tool Presetter Makes Production Smarter

2025-05-05 -

Zero-Point Positioning Systems in FMS: Specific Application Scenarios

2025-04-25